Fossilized

Fossilized: 3D printed concrete structures

Amalgamma: Alvaro Lopez Rodriguez, Francesca Camilleri, Nadia Doukhi, and Roman Strukov

University College of London, Bartlett School of Architecture

Mentors: Manuel Jimenez Garcia, Gilles Retsin, and Vicente Soler

2015

Breaking the mold of 3D printing? Already? That’s what four graduate students of the Bartlett School of Architecture (UCL) have succeeded at the doing with their project titled “Fossilized.”

The team, known as Amalgamma, is made up of Alvaro Lopez Rodriguez, Francesca Camilleri, Nadia Doukhi, and Roman Strukov.

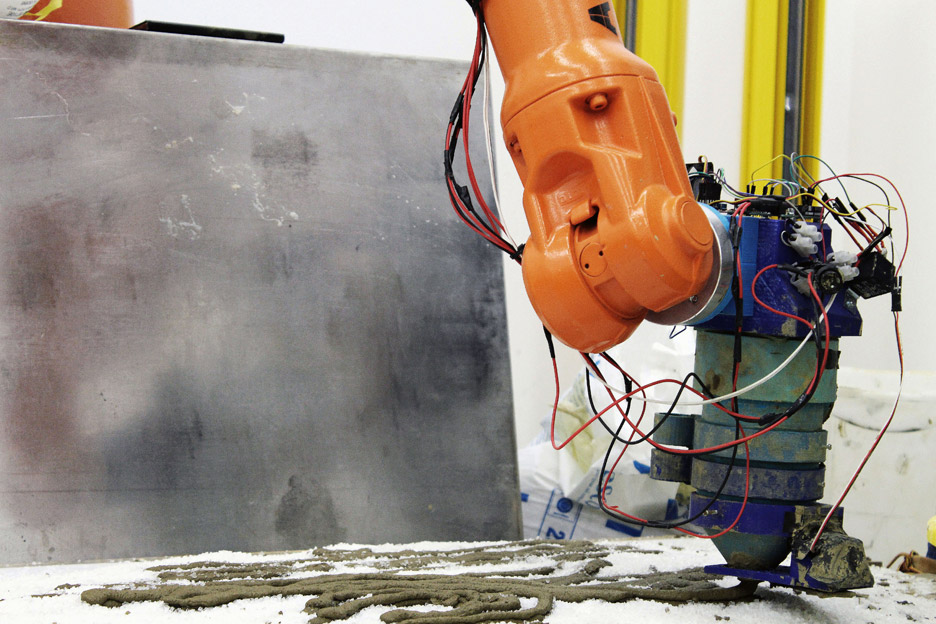

Under the mentorship of Manuel Jimenez Garcia, Gilles Retsin, and Vicente Soler, the design group created an innovative mechanism for printing 3D structures with the use of a robotic arm and using mainly concrete as the medium.

The goal? On one hand, to bring the spirit of craftsmanship back into the realm of architecture. On the other? Break the mold of current 3D printing practices which they currently see as being in a stagnant rut.

The team’s process involved combining two existing methods of 3D printing: extrusion and powder printing. Using an industrial-grade 3D robotic arm with customizable nozzles, the design team created a layer-driven design that forms its base around a central supporting structure. The team then used binders in the extrusion process to harden and fasten together the different pieces.

With each segment taking up to ten hours to print, the 1-centimeter resolution of the robotic arm produces an intricate pattern along the entirety of the monolith. The team applied the technique to produce furniture. More specifically, a tower and a chair.

One hurdle associated with printing architectural designs is, as the group concluded, the size of the 3D printer. In order to produce their designers, they required a 3D printer of larger or equal size. That is to say, in order to print a building in 3D as one continuous monolith, there would first need to be an equally sized 3D printing apparatus on premises.

3D printing is in a golden age of experimentation. People are applying this fairly new technique to create things never before thought “printable.”

In the architecture world, major design firms are testing experimental projects by printing modular 3D bridges or building panels.

Click and hold to rotate model.

Click and hold to rotate model.